Product Description

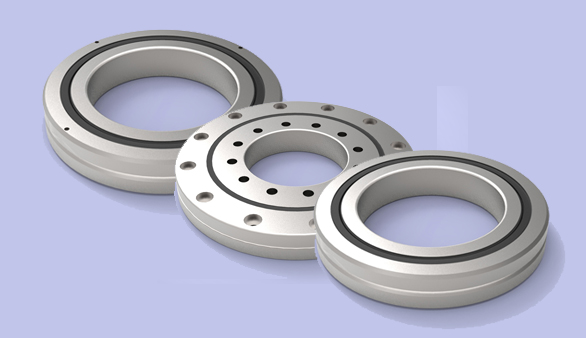

RKS.161.14.0544 lifting slewing bearing cross roller swing bearing slew bearing 640.3*474*56mm

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

product-list-1.html

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Straight Raceway |

| Material: | 50mn/42CrMo |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the challenges and solutions for managing complex loads and rotational accuracy in cross roller bearings?

Managing complex loads and maintaining rotational accuracy are crucial challenges in cross roller bearings. These bearings often encounter demanding operating conditions that require effective solutions to ensure optimal performance.

- Challenges:

- Solutions:

1. Complex Loads: Cross roller bearings may experience a combination of radial, axial, and moment loads. These loads can vary in magnitude, direction, and frequency, posing challenges in distributing the loads evenly across the bearing structure and minimizing stress concentrations.

2. Rotational Accuracy: Maintaining precise rotational accuracy is essential in applications where accurate positioning, motion control, and alignment are critical. Factors such as manufacturing tolerances, bearing clearance, and external disturbances can affect the rotational accuracy of cross roller bearings.

1. Optimized Bearing Design: Cross roller bearings are designed with specific load capacities and rigidity to handle complex loads. Manufacturers optimize the bearing’s internal geometry, material selection, and heat treatment processes to enhance load distribution and minimize stress concentrations. This enables the bearing to withstand varying loads and maintain structural integrity.

2. Precision Manufacturing: Achieving high rotational accuracy starts with precision manufacturing processes. Tight manufacturing tolerances and stringent quality control measures help ensure consistent dimensions and geometries of the bearing components. This minimizes variations and deviations that can impact rotational accuracy.

3. Preload and Clearance Adjustment: Proper preload and clearance adjustment are crucial for managing complex loads and maintaining rotational accuracy. Preload, achieved through controlled axial displacement or the use of spacers, eliminates internal clearance and enhances rigidity, reducing the effects of external forces. Careful adjustment of clearance ensures smooth operation while minimizing excessive play and maintaining accuracy.

4. Lubrication: Lubrication plays a vital role in managing complex loads and rotational accuracy. Appropriate lubrication reduces friction, minimizes wear, and dissipates heat generated during operation. The selection of the right lubricant, based on operating conditions and load requirements, ensures smooth rotation and helps maintain accuracy over extended periods.

5. Sealing and Contamination Control: Proper sealing and contamination control measures are essential for protecting cross roller bearings from external contaminants such as dust, dirt, and moisture. Seals and shields prevent ingress of harmful particles, maintaining the integrity of the bearing surfaces and minimizing wear that can affect rotational accuracy.

6. Mounting and Alignment: Accurate mounting and alignment of cross roller bearings are critical for achieving optimal performance. Careful attention should be given to the mounting surfaces, ensuring flatness and perpendicularity, to minimize misalignment and stress concentrations that can impact load distribution and rotational accuracy.

In summary, managing complex loads and rotational accuracy in cross roller bearings requires optimized bearing design, precision manufacturing, proper preload and clearance adjustment, appropriate lubrication, sealing and contamination control, as well as accurate mounting and alignment. By addressing these challenges and implementing effective solutions, cross roller bearings can deliver reliable and precise performance in a wide range of applications.

How do temperature variations and environmental conditions impact the performance of cross roller bearings?

Temperature variations and environmental conditions can significantly impact the performance of cross roller bearings. These factors affect the bearing’s materials, lubrication, and overall operation, and can lead to various performance issues. Here’s a detailed look at how temperature variations and environmental conditions impact cross roller bearings:

- Material Expansion and Contraction:

- Lubrication Performance:

- Thermal Expansion of Bearing Components:

- Corrosion and Rust:

- Contamination and Particle Ingress:

- Operating Life and Durability:

Temperature variations cause materials to expand or contract. Cross roller bearings typically consist of different components made of various materials, such as steel, aluminum, or plastics. When exposed to temperature changes, these materials expand or contract at different rates, which can affect the internal clearances and preload of the bearing. Excessive expansion or contraction can lead to changes in bearing tolerances, increased friction, and potential issues with fitting and alignment.

Temperature variations can impact the performance of lubricants used in cross roller bearings. Lubricants have specific viscosity characteristics at different temperatures. High temperatures can cause lubricants to thin out, leading to reduced film thickness and increased friction. Conversely, low temperatures can cause lubricants to thicken, making it challenging for them to flow properly and provide sufficient lubrication. Inadequate lubrication due to temperature variations can result in increased wear, higher operating temperatures, and potential bearing failure.

Temperature variations can also cause the bearing components themselves to expand or contract. This can affect the internal clearances and preload within the bearing. If the temperature rises, the bearing components may expand, leading to reduced internal clearances and potential binding or increased friction. On the other hand, lower temperatures can cause the bearing components to contract, resulting in increased internal clearances and potential play or reduced stiffness. These changes in clearances and preload can impact the precision, smoothness, and overall performance of the cross roller bearing.

Environmental conditions, including moisture, humidity, and exposure to corrosive substances, can lead to corrosion and rust formation on the bearing surfaces. Corrosion can degrade the bearing’s performance by increasing friction, causing surface damage, and reducing the effectiveness of lubrication. In severe cases, corrosion can lead to pitting, spalling, or premature failure of the cross roller bearing. Proper sealing, lubrication, and protection against corrosive elements are essential to mitigate the impact of environmental conditions on the bearing’s performance.

Environmental conditions can introduce contaminants, such as dust, dirt, or debris, into the bearing system. These particles can enter through open seals or shields or when the machine is operating in dusty or dirty environments. Contamination can cause abrasive wear, increase friction, and compromise the bearing’s precision and reliability. The presence of contaminants can also accelerate lubricant degradation and lead to lubricant contamination, further impacting the bearing’s performance.

Temperature variations and harsh environmental conditions can affect the operating life and durability of cross roller bearings. High temperatures can accelerate the aging and degradation of bearing materials, lubricants, and seals, reducing their overall lifespan. Exposure to extreme environmental conditions, such as high humidity or corrosive substances, can lead to premature wear and failure. Proper selection of materials, lubrication, and protective measures, such as seals and shields, is crucial to ensure the longevity and reliability of cross roller bearings in challenging operating environments.

In summary, temperature variations and environmental conditions have a significant impact on the performance of cross roller bearings. They can affect the materials, lubrication, internal clearances, and overall operation of the bearing. It is essential to consider these factors during the design, selection, and maintenance of cross roller bearings to ensure optimal performance, reliability, and longevity in various operating environments.

What are the common applications and industries where cross roller bearings are essential components?

Cross roller bearings find essential use in various applications and industries that require high precision, rigidity, and compact design. These bearings offer excellent rotational accuracy and load-carrying capacity, making them suitable for a wide range of demanding applications. Here’s a detailed overview of the common applications and industries where cross roller bearings are essential components:

- Robotics and Automation:

- Machine Tools:

- Medical and Healthcare:

- Aerospace and Aviation:

- Semiconductor Manufacturing:

- Optical and Precision Instruments:

- Industrial Machinery:

- Renewable Energy:

Cross roller bearings are extensively used in robotics and automation systems. They provide precise rotational motion and support heavy loads with minimal deflection. Cross roller bearings are commonly found in robot joints, robotic arms, manipulators, and other robotic mechanisms that require accurate positioning and smooth motion control.

In the machine tool industry, cross roller bearings are vital components in various equipment such as milling machines, grinding machines, lathes, and machining centers. These bearings provide the necessary rigidity and accuracy for spindle rotation, table movement, and other critical functions in machine tools.

The medical and healthcare sector relies on cross roller bearings for a range of applications. They are used in medical imaging equipment, including CT scanners, MRI machines, and X-ray systems, where precise and smooth movement is crucial. Cross roller bearings are also employed in surgical robots, patient tables, examination chairs, and other medical devices that require high precision and reliability.

Cross roller bearings play a significant role in the aerospace and aviation industry. They are utilized in aircraft landing gear systems, control surfaces, engine components, and satellite mechanisms. The compact design and high load-carrying capacity of cross roller bearings make them well-suited for aerospace applications that demand reduced weight and increased efficiency.

In semiconductor manufacturing, cross roller bearings are critical for precise wafer handling and positioning. They are used in wafer handling robots, inspection systems, lithography machines, and other semiconductor equipment. The high rigidity and low friction of cross roller bearings ensure accurate alignment and positioning of wafers during the manufacturing process.

Cross roller bearings are extensively employed in optical and precision instruments, including telescopes, microscope stages, coordinate measuring machines (CMMs), and optical inspection systems. These bearings provide stable and smooth motion control, allowing for accurate observations, measurements, and alignments in these instruments.

Various industrial machinery and equipment rely on cross roller bearings for their critical operations. They are used in printing machines, packaging equipment, textile machinery, industrial robots, and assembly lines. Cross roller bearings provide the necessary precision, load capacity, and reliability required in these industrial applications.

In the renewable energy sector, cross roller bearings are utilized in wind turbines and solar tracking systems. They enable the precise rotation and positioning of wind turbine blades and solar panels, ensuring optimal energy capture and conversion. Cross roller bearings contribute to the efficiency and reliability of renewable energy generation.

In summary, cross roller bearings are essential components in a wide range of applications and industries. They are commonly found in robotics and automation, machine tools, medical and healthcare equipment, aerospace and aviation systems, semiconductor manufacturing, optical and precision instruments, industrial machinery, and renewable energy systems. The unique characteristics of cross roller bearings make them indispensable for achieving accurate motion control, high load capacity, and long-term reliability in these demanding applications.

editor by CX 2024-02-21