What are the challenges and solutions for managing complex loads and rotational accuracy in cross roller bearings?

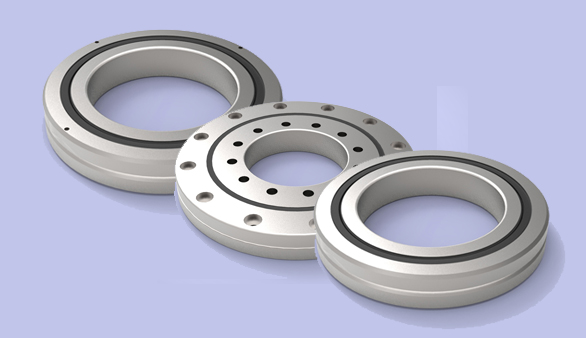

Managing complex loads and maintaining rotational accuracy are crucial challenges in cross roller bearings. These bearings often encounter demanding operating conditions that require effective solutions to ensure optimal performance.

- Challenges:

- Solutions:

1. Complex Loads: Cross roller bearings may experience a combination of radial, axial, and moment loads. These loads can vary in magnitude, direction, and frequency, posing challenges in distributing the loads evenly across the bearing structure and minimizing stress concentrations.

2. Rotational Accuracy: Maintaining precise rotational accuracy is essential in applications where accurate positioning, motion control, and alignment are critical. Factors such as manufacturing tolerances, bearing clearance, and external disturbances can affect the rotational accuracy of cross roller bearings.

1. Optimized Bearing Design: Cross roller bearings are designed with specific load capacities and rigidity to handle complex loads. Manufacturers optimize the bearing’s internal geometry, material selection, and heat treatment processes to enhance load distribution and minimize stress concentrations. This enables the bearing to withstand varying loads and maintain structural integrity.

2. Precision Manufacturing: Achieving high rotational accuracy starts with precision manufacturing processes. Tight manufacturing tolerances and stringent quality control measures help ensure consistent dimensions and geometries of the bearing components. This minimizes variations and deviations that can impact rotational accuracy.

3. Preload and Clearance Adjustment: Proper preload and clearance adjustment are crucial for managing complex loads and maintaining rotational accuracy. Preload, achieved through controlled axial displacement or the use of spacers, eliminates internal clearance and enhances rigidity, reducing the effects of external forces. Careful adjustment of clearance ensures smooth operation while minimizing excessive play and maintaining accuracy.

4. Lubrication: Lubrication plays a vital role in managing complex loads and rotational accuracy. Appropriate lubrication reduces friction, minimizes wear, and dissipates heat generated during operation. The selection of the right lubricant, based on operating conditions and load requirements, ensures smooth rotation and helps maintain accuracy over extended periods.

5. Sealing and Contamination Control: Proper sealing and contamination control measures are essential for protecting cross roller bearings from external contaminants such as dust, dirt, and moisture. Seals and shields prevent ingress of harmful particles, maintaining the integrity of the bearing surfaces and minimizing wear that can affect rotational accuracy.

6. Mounting and Alignment: Accurate mounting and alignment of cross roller bearings are critical for achieving optimal performance. Careful attention should be given to the mounting surfaces, ensuring flatness and perpendicularity, to minimize misalignment and stress concentrations that can impact load distribution and rotational accuracy.

In summary, managing complex loads and rotational accuracy in cross roller bearings requires optimized bearing design, precision manufacturing, proper preload and clearance adjustment, appropriate lubrication, sealing and contamination control, as well as accurate mounting and alignment. By addressing these challenges and implementing effective solutions, cross roller bearings can deliver reliable and precise performance in a wide range of applications.

What role do seals and shields play in protecting cross roller bearings from contaminants?

Seals and shields play a crucial role in protecting cross roller bearings from contaminants. These protective devices are designed to prevent the entry of foreign particles, such as dust, dirt, moisture, and other contaminants, into the bearing system. They offer several functions that contribute to the overall protection and longevity of cross roller bearings:

- Contamination Prevention:

- Retention of Lubrication:

- Protection against Moisture:

- Reduction of Friction and Wear:

- Prevention of Lubricant Contamination:

The primary role of seals and shields is to prevent contaminants from entering the bearing. They create a physical barrier that blocks the passage of particles into the internal components of the bearing. This is particularly important in industrial environments where cross roller bearings are exposed to various contaminants that can cause damage and premature wear. By effectively sealing the bearing, seals and shields help maintain a clean and controlled operating environment, ensuring the reliable and optimal performance of the bearing.

Seals and shields help retain the lubricant within the bearing, preventing its leakage and ensuring proper lubrication of the internal components. Lubrication is essential for reducing friction, minimizing wear, and dissipating heat within the bearing. The presence of seals or shields helps to retain the lubricating grease or oil, preventing its loss due to evaporation or contamination. This ensures that the cross roller bearing remains properly lubricated, promoting smooth operation and extending the service life of the bearing.

Moisture can be a significant source of contamination and can lead to corrosion and damage to the bearing components. Seals and shields act as a barrier against moisture ingress, preventing water or other liquids from reaching the internal parts of the bearing. By protecting against moisture, seals and shields help maintain the integrity of the bearing, reducing the risk of corrosion and preserving its performance and longevity.

Seals and shields also contribute to reducing friction and wear within the cross roller bearing. They provide an additional layer of protection and help minimize the contact between the rolling elements and the raceways. This reduces the frictional forces and wear on the bearing components, increasing their lifespan and improving overall efficiency. By reducing friction and wear, seals and shields help maintain the precision and performance of the cross roller bearing, ensuring smooth operation and minimizing energy losses.

Seals and shields play a vital role in preventing the contamination of the lubricant itself. They act as a barrier against external contaminants, such as dust and dirt, which can mix with the lubricant and degrade its quality. Contaminated lubricant can lead to increased friction, accelerated wear, and decreased performance of the cross roller bearing. The presence of seals and shields helps to maintain the cleanliness and integrity of the lubricant, ensuring its effectiveness in reducing friction and providing proper lubrication to the bearing components.

In summary, seals and shields play a critical role in protecting cross roller bearings from contaminants. They prevent the entry of foreign particles, retain lubrication, protect against moisture, reduce friction and wear, and prevent lubricant contamination. By effectively sealing the bearing and creating a controlled operating environment, seals and shields contribute to the longevity, reliability, and optimal performance of cross roller bearings in various applications and environments.

What are the common applications and industries where cross roller bearings are essential components?

Cross roller bearings find essential use in various applications and industries that require high precision, rigidity, and compact design. These bearings offer excellent rotational accuracy and load-carrying capacity, making them suitable for a wide range of demanding applications. Here’s a detailed overview of the common applications and industries where cross roller bearings are essential components:

- Robotics and Automation:

- Machine Tools:

- Medical and Healthcare:

- Aerospace and Aviation:

- Semiconductor Manufacturing:

- Optical and Precision Instruments:

- Industrial Machinery:

- Renewable Energy:

Cross roller bearings are extensively used in robotics and automation systems. They provide precise rotational motion and support heavy loads with minimal deflection. Cross roller bearings are commonly found in robot joints, robotic arms, manipulators, and other robotic mechanisms that require accurate positioning and smooth motion control.

In the machine tool industry, cross roller bearings are vital components in various equipment such as milling machines, grinding machines, lathes, and machining centers. These bearings provide the necessary rigidity and accuracy for spindle rotation, table movement, and other critical functions in machine tools.

The medical and healthcare sector relies on cross roller bearings for a range of applications. They are used in medical imaging equipment, including CT scanners, MRI machines, and X-ray systems, where precise and smooth movement is crucial. Cross roller bearings are also employed in surgical robots, patient tables, examination chairs, and other medical devices that require high precision and reliability.

Cross roller bearings play a significant role in the aerospace and aviation industry. They are utilized in aircraft landing gear systems, control surfaces, engine components, and satellite mechanisms. The compact design and high load-carrying capacity of cross roller bearings make them well-suited for aerospace applications that demand reduced weight and increased efficiency.

In semiconductor manufacturing, cross roller bearings are critical for precise wafer handling and positioning. They are used in wafer handling robots, inspection systems, lithography machines, and other semiconductor equipment. The high rigidity and low friction of cross roller bearings ensure accurate alignment and positioning of wafers during the manufacturing process.

Cross roller bearings are extensively employed in optical and precision instruments, including telescopes, microscope stages, coordinate measuring machines (CMMs), and optical inspection systems. These bearings provide stable and smooth motion control, allowing for accurate observations, measurements, and alignments in these instruments.

Various industrial machinery and equipment rely on cross roller bearings for their critical operations. They are used in printing machines, packaging equipment, textile machinery, industrial robots, and assembly lines. Cross roller bearings provide the necessary precision, load capacity, and reliability required in these industrial applications.

In the renewable energy sector, cross roller bearings are utilized in wind turbines and solar tracking systems. They enable the precise rotation and positioning of wind turbine blades and solar panels, ensuring optimal energy capture and conversion. Cross roller bearings contribute to the efficiency and reliability of renewable energy generation.

In summary, cross roller bearings are essential components in a wide range of applications and industries. They are commonly found in robotics and automation, machine tools, medical and healthcare equipment, aerospace and aviation systems, semiconductor manufacturing, optical and precision instruments, industrial machinery, and renewable energy systems. The unique characteristics of cross roller bearings make them indispensable for achieving accurate motion control, high load capacity, and long-term reliability in these demanding applications.

editor by CX 2024-02-11